Excavators are crucial equipment for mining, construction or building projects. Using the right excavator for the job increases productivity and efficiency.

One common excavator is the hydraulic shovel. Read on to discover the history of the hydraulic shovel and precisely how this machine works.

History

The powerful hydraulic shovels we have access to today are credited to William Smith Otis’ invention of the steam shovel in 1835. This piece of equipment was designed to complete the same work a group of men could achieve, but much faster.

Otis’ power shovel was equipped with a toothed bucket and a swinging boom with a dipper arm. To ensure mobility of the boom, men on the ground would pull on heavy duty ropes. The bucket dropping function was also triggered by a worker on the ground. This shovel was run on a steam engine and vertical boiler that was located at the rear of the machine.

This first shovel could move 380 cubic metres a day, and was equipped with a 1.1 cubic metre shovel.

Otis later developed the rail-mounted crane excavator, which was patented in 1839. This steam-powered machine became the world’s first ever bucket excavator.

Components

Otis’ inventions made possible the invention of the hydraulic shovel. These are also called power shovels. They are designed for mining purposes and other vigorous digging tasks.

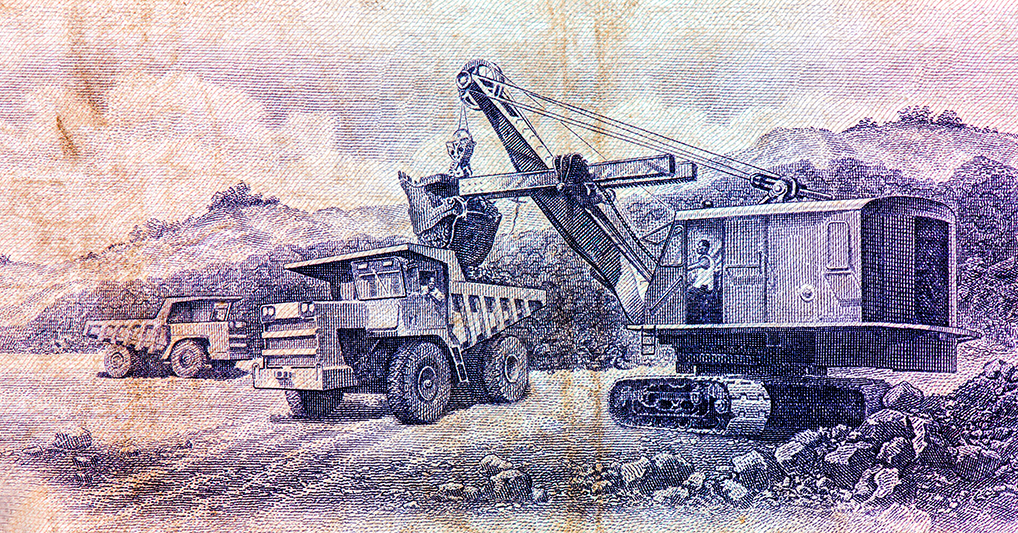

Hydraulic shovels generally haul soil, minerals, rocks and other heavy materials or debris. They comprise a heavy boom with a lifting arm/dipper shovel attached that can pivot on the boom. Attached to this is the bucket; because the dipper shovel can pivot, hydraulic shovels can be oriented with the bucket facing away from the cab or facing the machine’s cab. The digger bucket has a hanging bottom that the operator can open. The bucket fills up with forward and upward motions.

These heavy duty machines are equipped with driving mechanisms. The whole machine is mounted on a platform with wheels or tracks. The machine is powered by engine-driven pumps that provide pressure for motors and rams.

The hoe or backhoe attachment can replace the boom or bucket of the dipper shovel when digging below working level. This is because it helps to move the load toward the deck of the shovel rather than away from it. Recently, hydraulic hoes have been mounted on the rear of a tractor or on any shovel carrier when necessary.

If the machine needs to carry particularly heavy loads, a lifting crane may be attached instead of a digging shovel. The mobility of the load changes in this case. The load is moved laterally, by swinging or travelling and then being lowered down.

APT Spray Painting’s expert team frequently deals with heavy machinery jobs. We’re the experts when it comes to keeping them looking brand new and well-protected from the elements. We have the capability to paint any piece of machinery that fits our booth. For each and every job, we prioritise a quality finish and superior service. If you’re looking to keep your machinery in top condition for the long term, get in touch with us today.