In recent years, Artificial Intelligence (AI) has emerged as a transformative force across various industries, reshaping traditional processes and ushering in new levels of efficiency and innovation. The metal fabrication industry, known for its reliance on precision, skilled labour, and time-intensive processes, is no exception. As AI continues to evolve, it is poised to revolutionise metal fabrication, offering both significant opportunities and challenges. This blog explores the influence of AI in metal fabrication, highlighting its benefits, the potential drawbacks, and the future outlook for this critical industry.

The Rise of AI in Metal Fabrication

Metal fabrication, the process of cutting, shaping, and assembling metal structures, has traditionally been a labour-intensive industry. Skilled workers have long been at the heart of this sector, relying on their expertise to ensure precision and quality. However, as the demand for higher efficiency, greater customisation, and reduced waste intensifies, fabricators are increasingly turning to AI to meet these challenges.

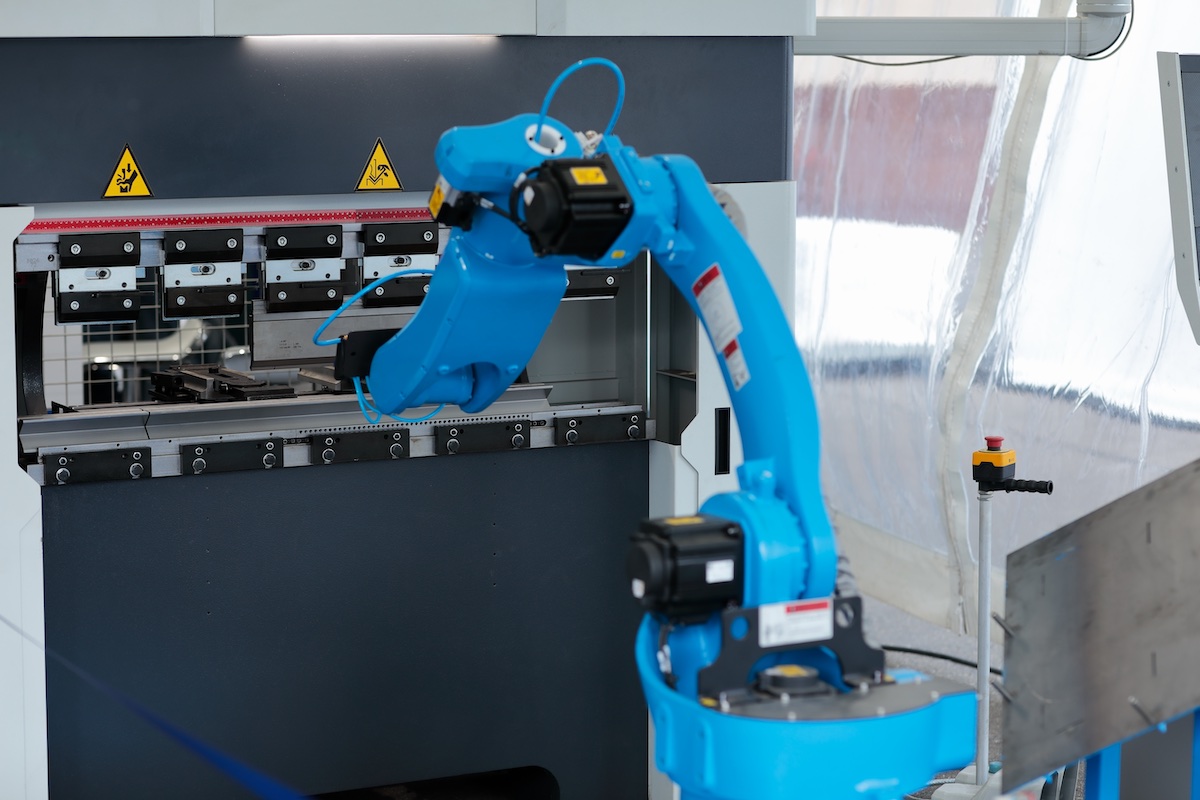

One of the most prominent roles AI plays in metal fabrication is process automation. AI-powered robots are now being deployed for tasks such as welding, cutting, and machining. These robots can perform repetitive tasks with remarkable precision, minimising the likelihood of human error and significantly speeding up production. For instance, in robotic welding, AI algorithms can adjust parameters in real time to account for variations in the environment or the materials being used, ensuring that each weld is consistent and of high quality.

Beyond automation, AI is also making significant strides in quality control. Traditionally, quality inspection in metal fabrication has been a manual, time-consuming process that relied heavily on the skill and attention to detail of human inspectors. AI, however, brings a new level of precision and efficiency to this task. By employing computer vision systems, AI can conduct real-time inspections of fabricated products, detecting defects or anomalies as they occur. This capability not only ensures that the final product meets the required specifications but also reduces the need for costly rework and minimises waste.

Strategic Applications of AI

While AI’s impact on the shop floor is often the focal point, its influence extends into the strategic and administrative domains of metal fabrication as well. AI is being leveraged to automate routine tasks such as creating presentations, drafting business proposals, and managing customer communications—tasks that, while not directly related to fabrication, are crucial to the overall success and growth of a business.

Tools like ChatGPT and Microsoft Copilot are being integrated into the daily operations of metal fabrication companies to streamline these front-office tasks. These AI tools can automate up to 80% of the work involved in creating a PowerPoint presentation or drafting a proposal. What might traditionally take hours can now be accomplished in a fraction of the time, freeing up valuable employee time for more complex and strategic activities. This application of AI highlights its broader potential to enhance efficiency across all aspects of a business, not just on the shop floor.

Optimising Workflows with AI

One of the most promising applications of AI in metal fabrication lies in workflow optimisation. In a typical metal fabrication shop, work-in-process (WIP) often acts as a buffer to absorb the variability inherent in manufacturing processes. Schedulers must account for uncertainties in setup times, material delivery, and other unpredictable factors, which often lead to inefficiencies and extended lead times.

AI has the potential to revolutionise this aspect of metal fabrication by optimising production schedules. Imagine a fabrication shop where AI generates the “perfect” schedule—one where work flows seamlessly from one workstation to the next with minimal wait times. This could dramatically reduce WIP and shorten lead times from weeks to days or even hours, leading to significant improvements in productivity.

Moreover, AI could play a critical role in continuous improvement on the shop floor. By integrating AI with shop management software, fabricators can create systems that learn and adapt over time. For example, operators can provide feedback that AI systems use to refine and optimise workflows continuously. This adaptive capability could lead to a more efficient manufacturing environment, where operations are constantly being fine-tuned to maximise output and reduce waste.

The Pros and Cons of AI in Metal Fabrication

The integration of AI in metal fabrication brings with it a host of benefits, but it also presents several challenges that must be carefully considered. Below, we explore some of the key pros and cons associated with the adoption of AI in the metal fabrication industry.

Pros:

1. Increased Efficiency: AI can significantly enhance the efficiency of production processes by optimising workflows, reducing waste, and ensuring that resources are utilised effectively. This leads to lower operational costs and higher output, enabling fabricators to meet the growing demands of their customers.

2. Improved Quality: AI-driven quality control systems offer a level of precision that is difficult to achieve through manual inspections. These systems can detect defects in real time, ensuring that the final product meets exacting standards. This not only reduces the need for rework but also improves customer satisfaction by delivering higher-quality products.

3. Enhanced Safety: The automation of dangerous tasks, such as welding, through AI, reduces the risk of workplace injuries. By taking over these hazardous jobs, AI creates a safer environment for workers, which can lead to lower insurance costs and higher employee morale.

4. Predictive Maintenance: AI’s ability to predict when machinery is likely to fail or require maintenance is another significant advantage. By analysing data from sensors and other sources, AI can anticipate equipment failures before they occur, allowing for proactive maintenance that minimises downtime and prevents costly repairs.

5. Innovation and Customisation: AI fosters innovation by enabling the development of new designs and the customisation of products to meet specific customer requirements. Generative AI, for example, can assist in creating optimised designs that use less material while maintaining structural integrity, leading to cost savings and increased sustainability.

Cons:

1. High Initial Costs: The implementation of AI technologies in metal fabrication requires a significant upfront investment in hardware, software, and employee training. This can be a barrier to entry, particularly for small to medium-sized businesses that may lack the resources to invest in these advanced technologies.

2. Job Displacement: The automation of tasks traditionally performed by human workers raises concerns about job displacement. As AI takes over more routine and repetitive tasks, there is a risk that some workers may be displaced, leading to potential social and economic challenges. However, this also presents an opportunity for reskilling and upskilling the workforce to handle more complex and strategic roles.

3. Complexity: Integrating AI into existing production processes can be a complex endeavour. It often requires significant changes to infrastructure and workflows, as well as the development of new skill sets among employees. Businesses need to be prepared for the challenges associated with this transformation and invest in the necessary resources to ensure a smooth transition.

4. Data Dependency: AI systems rely heavily on data to function effectively. Poor data quality or insufficient data can lead to inaccurate predictions and inefficiencies in the manufacturing process. Ensuring that data is accurate, complete, and up-to-date is crucial for the successful implementation of AI in metal fabrication.

5. Cybersecurity Risks: As metal fabrication processes become more digitised and interconnected, they also become more vulnerable to cyberattacks. Protecting sensitive information and ensuring the integrity of AI systems is essential to prevent disruptions in production and safeguard against potential breaches.

The Future of AI in Metal Fabrication

The influence of AI in metal fabrication is still in its early stages, but its potential is undeniable. As AI technologies continue to evolve and mature, we can expect even more significant changes in how metal fabrication is conducted. However, the successful integration of AI will require a balanced approach that takes into account both the benefits and the challenges. Businesses must be strategic in their adoption of AI, ensuring that they have the necessary infrastructure, skills, and resources in place to support these advanced technologies. Additionally, the human element will remain critical—AI can enhance human capabilities, but it cannot replace the creativity, intuition, and judgement that skilled workers bring to the industry.