The lifecycle of an asset is quite often supported by a document usually called a Painting Specification.

This specification ensures that expensive machinery and equipment receives a paint based protective coating that is fit for the purpose of the asset(s). Each asset will have a different paint specification document depending on its circumstances, material and/or purpose. For example, there will be a specification for equipment that reaches high temperatures / low temperatures, another for equipment that is being overhauled, another may be for brand new equipment and another for minor repairs.

The system/paint specification will include vital information such as:

- Precise details of how the machinery needs to be prepared for painting

- What paint needs to be used – e.g. brand and type

- The required wet and dry thickness of paint needed for the primer, the intermediate coat and the top coat

- The colour(s) that the equipment should be painted

Below we have outlined the steps that we often follow when it comes to painting specifications:

Preparation

Quite often, a piece of equipment will arrive at our workshop that first needs to be sandblasted before beginning any paint specification work. In this case, some of the more vulnerable areas of the equipment will need to be masked in order to protect them from the harsh impact of the sandblasting process.

Below are images of a hooking case we recently painted, during the preparation stage:

After sandblasting has been completed, the 2 pack paint primer needs to be applied almost immediately in order to stop blush rust from forming. At APT, our sandblaster is located right next door which means that our customers’ equipment is always primed immediately after blasting and there’s no need to organise any transport. As soon as the equipment arrives back to us, it is cleaned, jigged and made ready for spray painting. Then it’s straight into the spray paint booth for priming.

If sandblasting isn’t needed, then the equipment substrate will be properly prepared to ensure that the primer will adhere to the equipment. Every substrate needs a different type of preparation process.

Primer

The exact brand and type of paint will have been nominated in the paint specification. At APT, we always make sure to apply the paint exactly as the manufacturer states in the paint Technical Data Sheet. Once the primer is applied (and while the paint is still wet), we measure and document the wet film thickness and once the primer is dry, we also measure the dry film thickness. We do this to ensure that it meets the Painting Specification that has been provided. The paint will now be left to cure. The exact curing time varies depending on the type of primer, the weather and temperature but we generally allow 24 hours for the primer to cure. Below is a photo of the same hooking case after the primer phase:

Intermediate Coat

Paint Specifications often call for an intermediate coat of paint. This intermediate coat of paint might be the same as the primer or the top coat – or it may be different. It will also need to be applied over the primer within a given period of time. At APT we always make sure to strictly follow the requirements of the overcoat interval times. Like with the primer, we measure and document both the wet and dry film thickness of the paint, then it is left to cure. Generally, we leave 24 hours for the intermediate coat to cure.

Top Coat

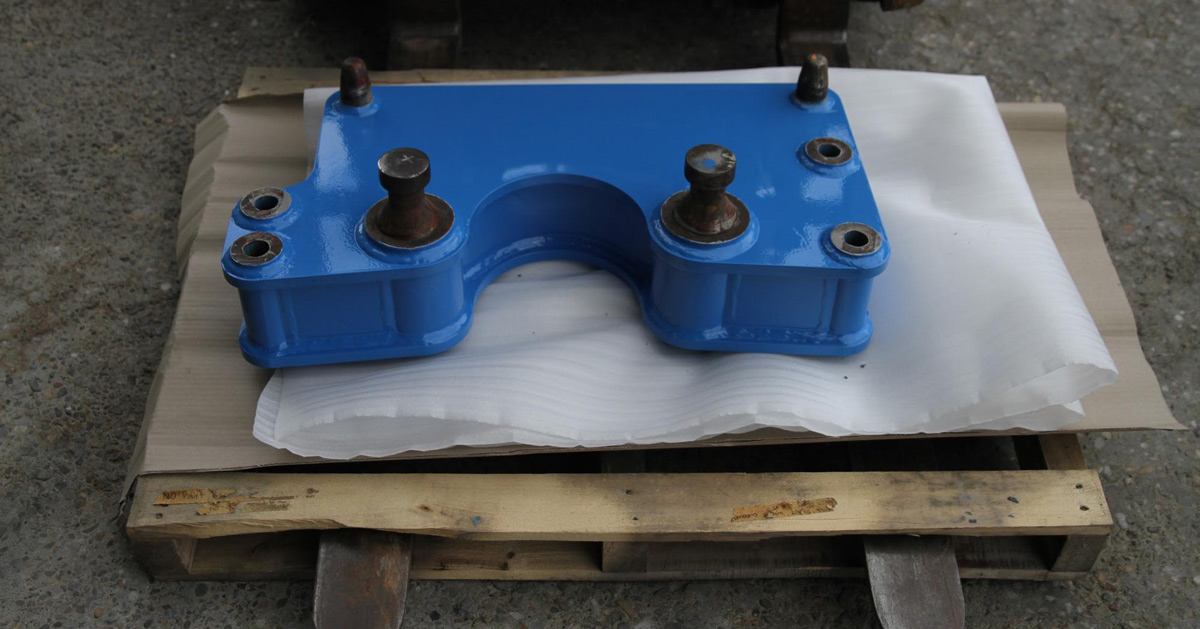

A paint specification will call for a given brand and type of paint to be used as the top coat and most often, a specific colour will be nominated. This top coat generally has different protective attributes that complement the protective attributes of the primer and intermediate coats. The top coat is applied exactly as per the manufacturer’s specifications. After the top coat is spray painted, the paint thickness is measured and the paint is left to fully cure. Below are images of the hooking case after the top coat had been completed, the job was finished and it was ready to be transported back to the client:

Transport

Often, the equipment needs to be left to cure for a number of days as transport can damage the paint when not fully cured.

At APT we specialise in these sorts of ‘painting to spec’ jobs. While the steps are time-consuming, it’s crucial each part of the process is followed properly. In our experience, shortcuts never lead to a high-quality result and our clients always value an expert result over a rushed job. What’s more, if you don’t already have a paint specification, we are always happy to make a custom paint system for you! To learn more about our services, get in touch with us today!